November 11, 2023

By admin

THE ART OF CRAFTING A LEATHER JACKET: A JOURNEY FROM HIDE TO CHIC

Crafting a leather jacket is a skillful art, turning raw hides into a fashionable and enduring piece that blends classic techniques with modern style.

The leather jacket, an iconic garment that exudes timeless style and rebellious charm, has been a fashion staple for decades. Behind its allure lies a meticulous and intricate process that transforms raw animal hides into a wearable work of art. In this blog, we’ll delve into the fascinating journey of how a leather jacket is made, from the selection of hides to the final product that graces the shoulders of fashion enthusiasts worldwide.

The tanning process stabilizes the collagen fibers in the hide, preventing it from decomposing and giving the leather its characteristic strength and texture.

Raw Material Selection

The journey begins with the careful selection of raw materials. High-quality leather jackets require premium hides, typically sourced from cows, goats, or sheep. The choice of leather depends on the desired end product—whether it’s a rugged biker jacket or a sophisticated bomber. The hides must be free from defects, scars, and blemishes to ensure a smooth and flawless finish.

Raw Material leather Selection

Pre-Tanning Preparation

Before tanning, the hides undergo a series of preparatory steps. This includes removing hair, fleshing, and soaking to clean and soften the material. The hides are then treated with salt to prevent bacterial growth and preserve them during transportation.

The hides are then treated with salt

Tanning Process

Tanning is a critical step in turning raw hides into durable and flexible leather. Traditional tanning methods involve using vegetable extracts or mineral salts, while modern techniques often employ chemicals.Related Products

-

ANGELIC Grey Leather Jacket For Women

$299.00 – $329.00Price range: $299.00 through $329.00 -

APEX Brown Leather Jacket For Men

$299.00 – $329.00Price range: $299.00 through $329.00 -

ARCHER Brown Leather Jacket For Men

$299.00 – $329.00Price range: $299.00 through $329.00 -

Arctic Blue Sherpa Denim Jacket

$299.00 – $329.00Price range: $299.00 through $329.00

Tanning Process

Dyeing and Finishing

Once tanned, the leather is dyed to achieve the desired color. This can be done using natural or synthetic dyes, depending on the manufacturer’s preferences. After dyeing, the leather undergoes finishing processes such as buffing, oiling, and polishing to enhance its appearance, texture, and overall quality.

Dyeing and Finishing

Cutting and Pattern Making

With the prepared leather in hand, skilled artisans create a pattern for the jacket. This pattern serves as a template for cutting the leather into individual pieces, including the body, sleeves, and various panels. Precision is crucial at this stage to ensure consistency and accuracy in the final product.

Cutting and Pattern Making

Assembly and Stitching

The cut leather pieces are then skillfully assembled by expert craftsmen. Using heavy-duty sewing machines or hand-stitching techniques, these artisans meticulously bring the jacket to life. Reinforcements may be added to critical areas for durability, and pockets, zippers, and other hardware are carefully integrated.

Assembly and Stitching

Detailing and Embellishments

To add character and style, designers incorporate details and embellishments. This can include quilting, embroidery, studs, or patches, depending on the jacket’s design. These elements contribute to the uniqueness of each leather jacket.

Detailing and Embellishments

Quality Control

Before the jackets hit the shelves, rigorous quality control measures are in place. Each piece undergoes inspection to ensure that it meets the brand’s standards for craftsmanship, durability, and aesthetic appeal.

Quality Control

Final Treatments

In the final stages, the leather jackets may undergo additional treatments for waterproofing, stain resistance, or other specific features. This step adds functionality to the garment, ensuring that it not only looks great but also stands up to the challenges of everyday wear.

Final Treatments

Packaging and Distribution

Once approved, the leather jackets are carefully packaged and prepared for distribution. From the hands of skilled artisans to the closets of fashion enthusiasts, each jacket embarks on its own unique journey.

Packaging and Distribution

Conclusion

The creation of a leather jacket is a labor-intensive process that combines traditional craftsmanship with modern techniques. From the selection of premium hides to the final stitches, every step is a testament to the dedication and skill of the artisans involved. The result is not just a garment but a piece of wearable art that carries with it the rich history and craftsmanship of leatherworking traditions.Share:

Share on facebook

Share on twitter

Share on linkedin

Share on telegram

Admin

Author

Recent Posts

Follow Us

Related Posts

November 12, 2025

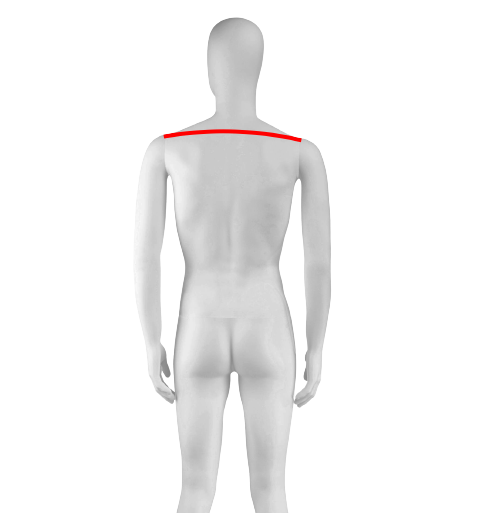

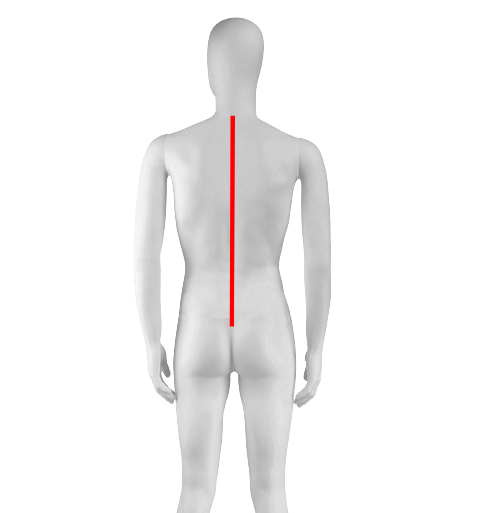

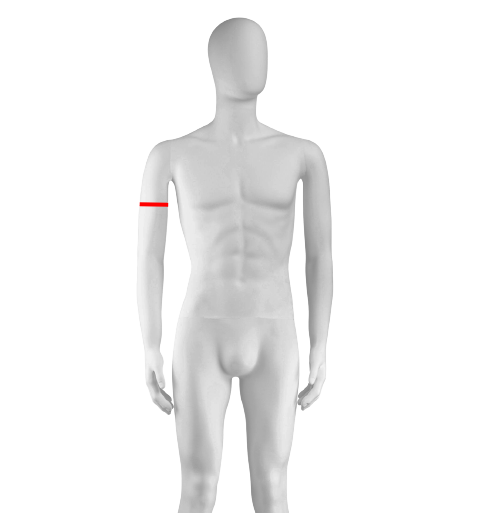

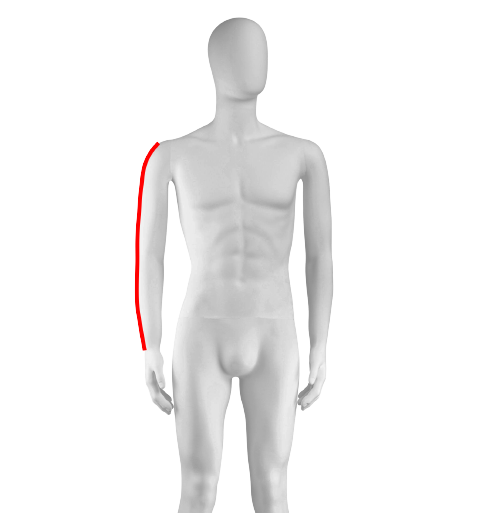

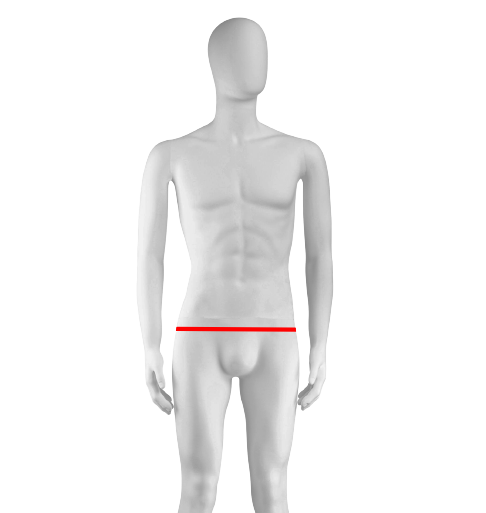

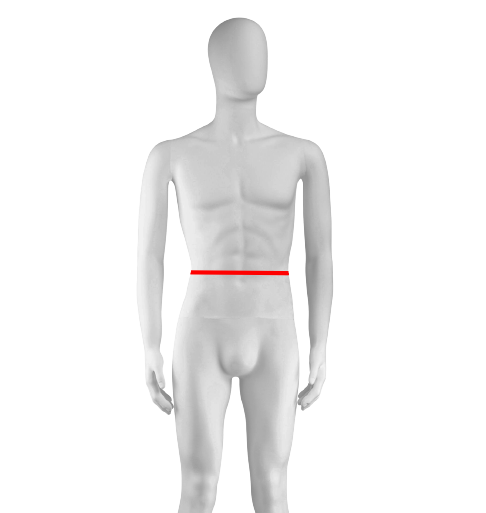

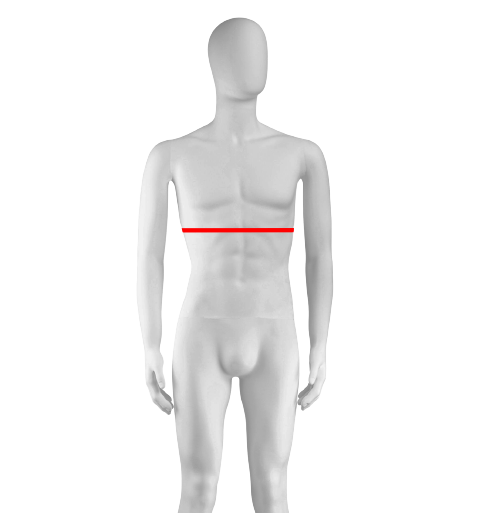

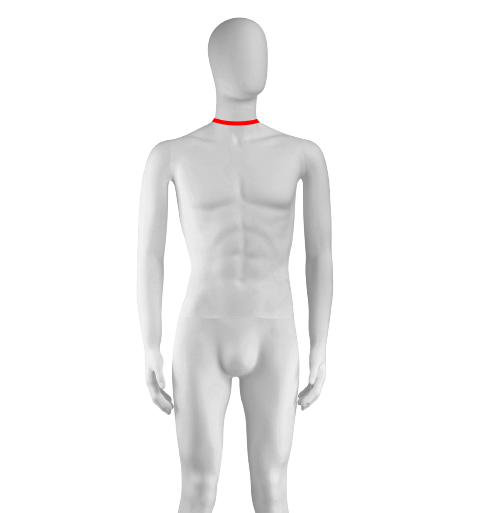

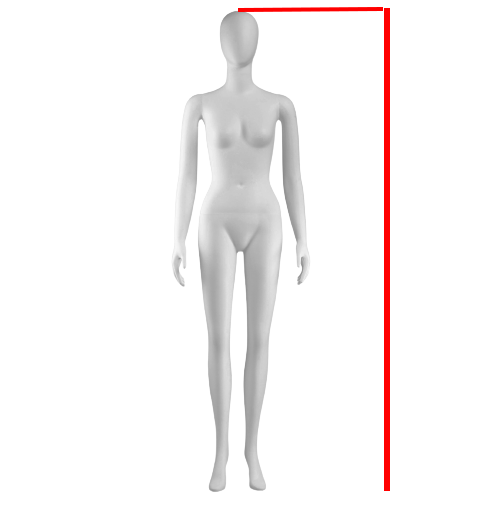

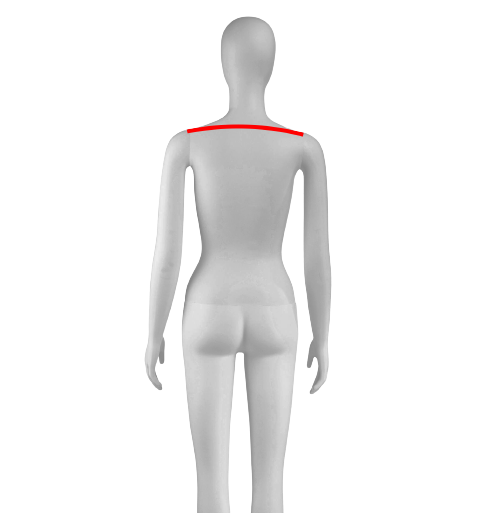

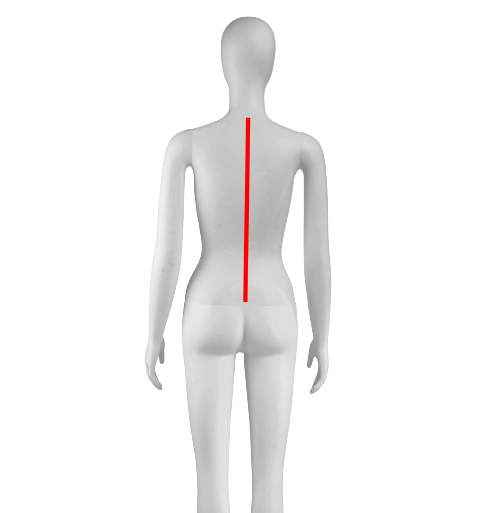

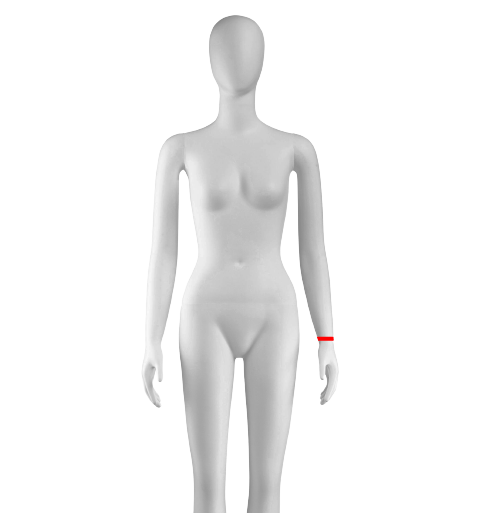

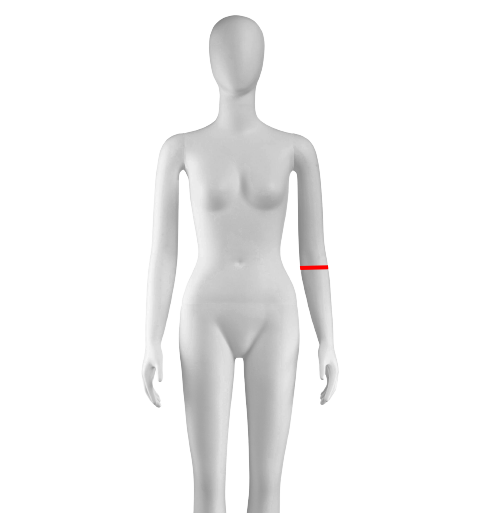

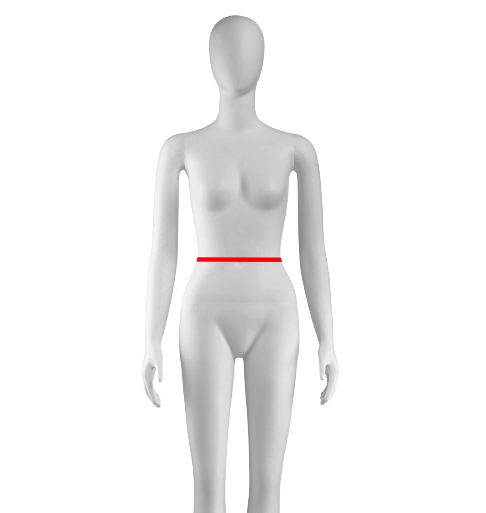

How to Measure Yourself for the Perfect Leather Jacket Fit: Your Ultimate Guide by LAMMBERG

A leather jacket is more than just outerwear—it’s a statement…

October 29, 2025

Top 10 Genuine Leather Jackets for men and women in USA You Can Buy Online

Meta Description:Discover the top 10 genuine leather jackets in…

October 10, 2025

Top 10 Men’s Leather Coats and Trench Coats in 2025

Every year, new styles redefine men’s fashion, but one thing…